Industrial Series SF SF61220CY

Industrial Series SF SF61220CY

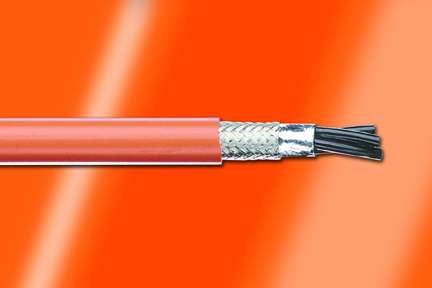

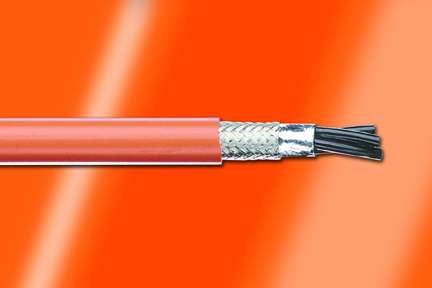

This picture is representative only and may not match the specific configuration of the product listed on this page. Please refer to the product specifications for more information on this part number and its exact configuration.

Download RoHS Certificate

Alpha Wire's Series SF cables are designed specifically for servo motors and servo drives. Series SF cable is the right choice if you need increased flexibility for your power servo applications.

Industrial Series SF Key features:

Power cable

- 4-conductor power cable, with or without brake pair

- 18 – 8 AWG

- Thermoplastic elastomer jacket

- SF Series offers increased flexibility

- UL Type TC-ER (600V)

- UL Type WTTC (1000V)

- Sunlight resistant

- UL Oil Res I/II

Control cable

- 3 to 6 pairs for resolver applications

- 9 conductors for encoder applications

- 20 AWG

- Polyolefin insulation

- Thermoplastic elastomer jacket

Construction

| Diameters (In) | ||||||||||||||||||||

| 1) Component 1 | 4 X 1 COND | |||||||||||||||||||

| a) Conductor | 16 (26/30) AWG Tinned Copper | 0.060 | ||||||||||||||||||

| b) Insulation | 0.016" Wall, Nom. PVC/ 0.005" Wall NYLON | 0.102 | ||||||||||||||||||

| (1) Print | ALPHANUMERIC NUMBERS - 1-ONE ALTERNATING AND INVERTED | |||||||||||||||||||

| (2) Color Code | Alpha Wire Color Code KX | |||||||||||||||||||

| ||||||||||||||||||||

| 2) Component 2 | 2 X 1 PAIR | |||||||||||||||||||

| a) Conductor | 18 (19/30) AWG Tinned Copper | 0.050 | ||||||||||||||||||

| b) Insulation | 0.016" Wall, Nom. PVC/ 0.005" Wall NYLON | 0.092 | ||||||||||||||||||

| (1) Color Code | Alpha Wire Color Code A | |||||||||||||||||||

| ||||||||||||||||||||

| c) Pair | 2/Cond Cabled Together | |||||||||||||||||||

| (1) Twists: | 6.0 Twists/foot (min) | |||||||||||||||||||

| Individually Applied: | ||||||||||||||||||||

| d) Shield: | Flex Alum/Mylar Tape, 25% Overlap, Min. | |||||||||||||||||||

| (1) Foil Direction | Foil Facing Out | |||||||||||||||||||

| (2) Drain Wire | 22 (7/30) AWG Tinned Copper | |||||||||||||||||||

| (3) Braid | Tinned Copper,85% Coverage, Min. | |||||||||||||||||||

| e) Jacket | 0.016" Wall, Nom.,TPE | 0.242 (0.253 Max.) | ||||||||||||||||||

| (1) Color(s) | NATURAL | |||||||||||||||||||

| (2) Print | ALPHANUMERIC NUMBERS - 1-ONE ALTERNATING AND INVERTED | |||||||||||||||||||

| 3) Cable Assembly | 6 Components Cabled | |||||||||||||||||||

| a) Twists: | 2.7 Twists/foot (min) | |||||||||||||||||||

| b) Orientation: | Components to be arranged from INSIDE LAYER to OUTSIDE LAYER | |||||||||||||||||||

| c) Core Wrap | REMAY Tape, 25% Overlap, Min. | |||||||||||||||||||

| 4) Shield: | A/P/A Tape, 25% Overlap, Min. | |||||||||||||||||||

| a) Drain Wire | 22 (7/30) AWG Tinned Copper | |||||||||||||||||||

| b) Braid | Tinned Copper,85% Coverage, Min. | |||||||||||||||||||

| 5) Jacket | 0.065" Wall, Nom.,TPE | 0.645+/- 0.032 | ||||||||||||||||||

| a) Color(s) | ORANGE | |||||||||||||||||||

| b) Jacket Separator | Tissue Tape, 25% Overlap, Min. | |||||||||||||||||||

| c) Print | ALPHA WIRE-* P/N SF61220CY 4C 16 AWG 2PR 18 AWG TFFN E324185 (UL) WTTC 90C 1000 VOLT OR (UL) TC-ER 90C 600V OIL RES I/II SUN RES OR C(UL) CIC CONTROL/TC 90C PVC/NYLON INS SHIELDED FT4 4C16 2PR18 --- LLXXXXXX CSA AWM I/II A/B 90C 600V FT4 CE ROHS (DATE CODE) (SEQ FOOTAGE) * = Factory Code [Note: Product may have c(UL) or CSA markings depending upon plant of manufacture.] | |||||||||||||||||||

Applicable Specifications

| 1) UL | ||

| a) Component 1 | TFFN | 90°C / 600 VRMS |

| b) Component 2 | TFFN | 90°C / 600 VRMS |

| c) Overall | TC | 90°C / 600 VRMS |

| EXPOSED RUN | ||

| OIL RES I/II | ||

| SUN RES | ||

| WTTC | 90°C / 1000 VRMS | |

| 2) CSA International | AWM I/II A/B | 90°C / 600 VRMS |

| FT4 | ||

| C(UL) CIC CONTROL | 90°C / 600 VRMS | |

| C(UL) TC | 90°C / 600 VRMS | |

| 3) Other | Conductors NEMA Class K | |

| 4) CE: | EU Low Voltage Directive 2014/35/EC | |

Environmental

| 1) EU Directive 2011/65/EU(RoHS2): | ||

| All materials used in the manufacture of this part are in compliance with European Directive 2011/65/EU regarding the restriction of use of certain hazardous substances in electrical and electronic equipment. Consult Alpha Wire's web site for RoHS C of C. | ||

| 2) REACH Regulation (EC 1907/2006): | ||

| This product does not contain Substances of Very High Concern (SVHC) listed on the European Union's REACH candidate list in excess of 0.1% mass of the item. For up-to-date information, please see Alpha's REACH SVHC Declaration. | ||

| 3) California Proposition 65: | The outer surface materials used in the manufacture of this part meet the requirements of California Proposition 65. | |

Properties

| Physical & Mechanical Properties | |

|---|---|

| 1) Temperature Range | -30 to 90°C(static), -5 to 90°C (dynamic) |

| 2) Bend Radius | 10X Cable Diameter(static), 10X Cable Diameter(dynamic) |

| 3) Pull Tension | 179 Lbs, Maximum |

| 4) Sunlight Resistance | Yes |

| Electrical Properties | (For Engineering purposes only) |

| 1) Voltage Rating | 600 VRMS |

| 2) Component 1 | |

| a) Capacitance | 48 pF/ft @1 kHz, Nominal Conductor to Conductor |

| b) Ground Capacitance | 86 pF/ft @1 kHz, Nominal |

| c) Inductance | 0.18 µH/ft, Nominal |

| d) Conductor DCR | 4.5 Ω/1000ft @20°C, Nominal |

| 3) Component 2 | |

| a) Mutual Capacitance | 48 pF/ft @1 kHz, Nominal |

| b) Ground Capacitance | 86 pF/ft @1 kHz, Nominal |

| c) Characteristic Impedance | 46 Ω |

| d) Inductance | 0.19 µH/ft, Nominal |

| e) Conductor DCR | 6.1 Ω/1000ft @20°C, Nominal |

| f) Component Shield DCR | 2.9 Ω/1000ft @20°C, Nominal |

| 4) OA Shield DCR | 1.21 Ω/1000ft @20°C, Nominal |

Other

| Packaging | Flange x Traverse x Barrel (inches) |

| a) 1000 FT | 30 x 14 x 12 Continuous length |

| b) 500 FT | 24 x 14 x 12 Continuous length |

| c) 100 FT | 16 x 11 x 8 Continuous length |

| [Spool dimensions may vary slightly] | |

| Notes: | |

| a) Suitable for use in Industrial Machinery per the requirements of NFPA-79 | |

| b) Suitable for intermittent or light duty flexing where cycle count will be less than 1,000,000 cycles. | |