Xtra-Guard Flex 87003

Xtra-Guard Flex 87003

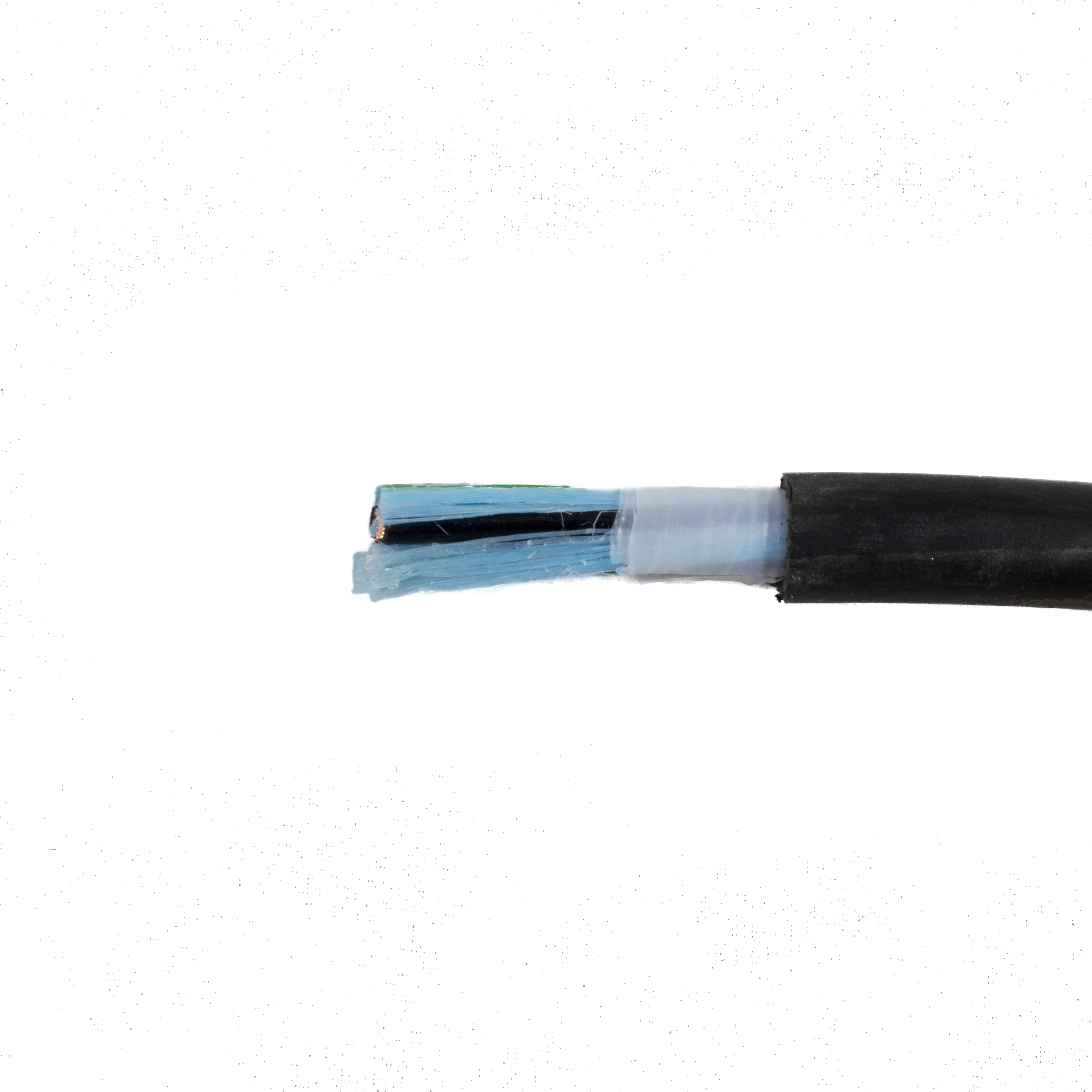

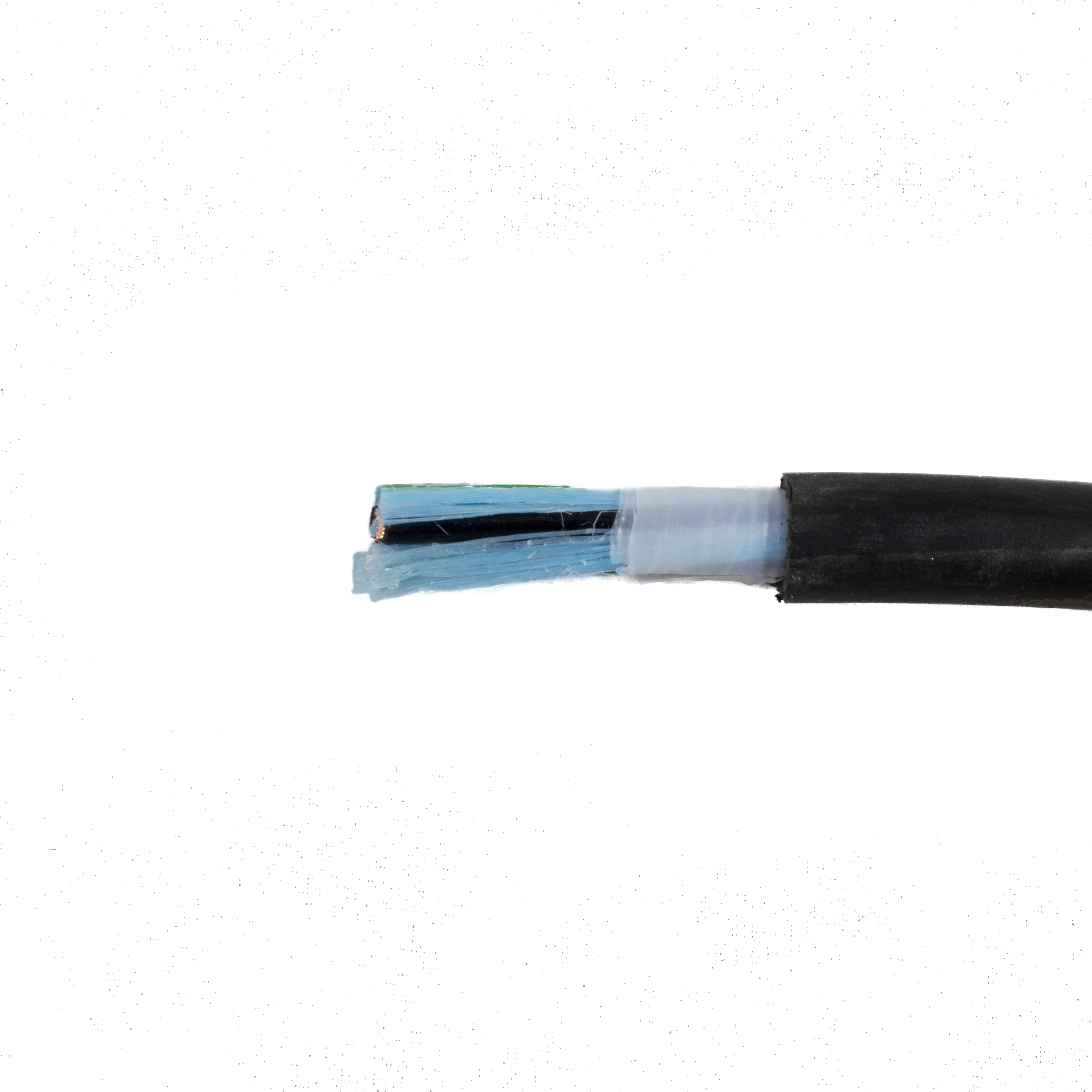

This picture is representative only and may not match the specific configuration of the product listed on this page. Please refer to the product specifications for more information on this part number and its exact configuration.

Download RoHS Certificate

Xtra-Guard® Flex - Wide variety of flexing applications

- Long-lasting flex cables designed to provide excellent performance in high-flex, high torsion, and continuous-flex applications, such as motion control and robotics

- Rated for up to 14 million flex life cycles (85000 series), up to 6 Million flex life cycles (86000 series)

- Available in a variety of configurations allowing exactly the right cable to be selected for the application

- Rounded geometry helps insure a liquid-tight installation per IP67 or NEMA 6

- Supra-Shield provides precise EMI interference resistance for your specific application is easily achievable with the available standard flex, torsional flex, and continuous flex applications

- Meets NFPA Standard 79 for industrial machinery*

*Product must be used in accordance with the respective AWM style. Click here for more details.

Construction

| Diameters (In) | ||||||||||||||

| 1) Component 1 | 3 X 1 COND | |||||||||||||

| a) Conductor | 24 (7/32) AWG Bare Copper | 0.024 | ||||||||||||

| b) Insulation | 0.016" Wall, Nom. TPES | 0.056 | ||||||||||||

| (1) Print | ALPHANUMERIC NUMBERS - 1-ONE ALTERNATING AND INVERTED | |||||||||||||

| (2) Color Code | Alpha Wire Color Code KX | |||||||||||||

| ||||||||||||||

| 2) Cable Assembly | 3 Components Cabled | |||||||||||||

| a) Twists: | 4.0 Twists/foot (min) | |||||||||||||

| b) Orientation: | Components to be arranged from INSIDE LAYER to OUTSIDE LAYER | |||||||||||||

| c) Core Wrap | PTFE(skived) Tape, 25% Overlap, Min. | |||||||||||||

| 3) Jacket | 0.050" Wall, Nom.,Polyurethane (TPU) | 0.227 (0.240 Max.) | ||||||||||||

| a) Color(s) | BLACK | |||||||||||||

| b) Print | ALPHA WIRE-* P/N 87003 XTRAGUARD(R) FLEXIBLE TORSION CABLE - RU AWM 20234 VW-1 OR CRU AWM I/II A/B 80C 600 VOLTS FT2 CE ROHS (SEQ FOOTAGE) * = Factory Code | |||||||||||||

Applicable Specifications

| 1) UL | ||

| a) Component 1 | AWM/STYLE 10162 | 80°C / 600 VRMS |

| b) Overall | AWM/STYLE 20234 | 80°C / 600 VRMS |

| VW-1 | ||

| 2) CSA International | C(RU) AWM I/II A/B FT2 | 80°C / 600 VRMS |

| 3) CE: | EU Low Voltage Directive 2014/35/EU | |

Environmental

| 1) CE: EU Directive 2011/65/EU(RoHS2), EU Directive 2015/863/EU (RoHS3): | ||

| This product complies with European Directive 2011/65/EU (RoHS Directive) of the European Parliament and of the Council of 8 June 2011 and the amending Directive 2015/863/EU of 4 June 2015 . No Exemptions are required for RoHS Compliance on this item. | ||

| 2) REACH Regulation (EC 1907/2006): | ||

| This product does not contain Substances of Very High Concern (SVHC) listed on the European Union's REACH candidate list in excess of 0.1% mass of the item. | ||

| 3) California Proposition 65: | This product may contain substances known to the State of California to cause Cancer or Reproductive Harm, but is exempt from labeling based on the Consent Judgement. See the Alpha Wire website for more information. | |

Properties

| Physical & Mechanical Properties | |

|---|---|

| 1) Temperature Range | -30 to 80°C(static), -10 to 80°C (dynamic) |

| 2) Bend Radius | 10X Cable Diameter(static), 15X Cable Diameter(dynamic) |

| 3) Pull Tension | 10.6 Lbs, Maximum |

| Electrical Properties | (For Engineering purposes only) |

| 1) Voltage Rating | 600 VRMS |

| 2) Inductance | 0.22 μH/ft, Nominal |

| 3) Conductor DCR | 22.7 Ω/1000ft @20°C, Nominal |

Other

| Packaging | Flange x Traverse x Barrel (inches) |

| a) Bulk(Made-to-order) |